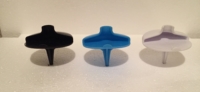

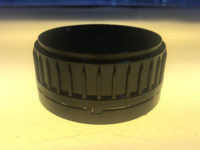

MDS Manufacturing has 9 plastic injection molding machines ranging in size from 50 ton to 500 tons. Our custom plastic injection molded products cover a variety of parts serving many diverse markets including infant care, cookware, outdoor and agricultural products, organizational items and many other markets.

We are continuously improving and upgrading our equipment and our quality processes to ensure that we maintain the highest standards in accuracy and timeliness when it comes to customer delivery. Custom plastic injection molding starts with communication and innovation that develops into quality products that exceed industry and customer standards.

High-Speed Electric and Hydraulic Injection Molding Machines

Robotics handle parts extraction, separation & secondary processes

Press sizes ranging fro 85 to 550 tons

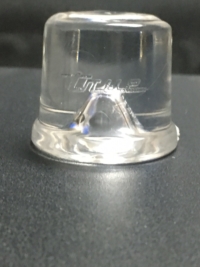

We are the only liquid silicone molder in the Midwest, a benefit for companies looking to reduce their shipping costs. All Engel machines are state-of-the-art LSR machines that combine flexibility with stability while maintaining that soft feel.

Industries we serve include the infant care industry where we have become a leader in producing liquid silicone injected parts. . We are committed to growth and have the ability to adapt to changing markets which make us the perfect choice for any of your LSR needs. LSR industry capabilities, besides the infant care industry, include cosmetics, medical, cookware, food service, and electronics.

Only liquid silicon molder in the Midwest

Modern press sizes up to 150 tons

State of the art Engel LSR machines

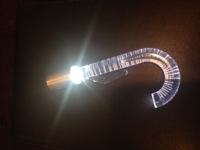

MDS Manufacturing has three of the latest technology AOKI ISBM machines. Injection stretch blow molding uses a method of biaxiel stretching which increases strength and clarity of bottles and reduces the overall weight of a container by 10-15%.

Our commitment to quality products, high-tech machinery, skilled personnel and strong leadership have allowed us to grow this segment of our business over the last two years by 35%. We are one of the largest producing ISBM plants for the infant care business in the United States, producing over 1,000,000 parts per year.

We use the latest ISBM technology

We are the largest producing ISBM plant for infant care in the U.S.

We produce 1,000,000+ parts/year

We are capable of running 24 hours per day, seven days a week

We are centrally located in the Midwest to allow quicker delivery and lower shipping costs

Additional Services

Keep production lines moving with one-stop molding and assembly processing. MDS provides Assembly services for many products that require individual handling and then can be bulk packed for customers. We also provide individual assembly service with complete packaging for retail.

MDS knows what it takes to keep a production line moving to its highest capacity. Our skilled operators are able to keep precise quality control while also providing individual assembly and custom packaging for each customer’s needs.

MDS has several partners that will create custom hot stamping die’s and logos allowing us to do in-house hot stamping for single color transfers. In addition, MDS also has key relationships with outside vendors in order to meet customer’s demands for more intricate and complex hot stamping requirements.

MDS utilizes the Deco Tech system for all of our customer’s custom pad printing needs.